Single Energy Impact Hammers

SIH10 Series, Model SIH200

IEC Standards: 60068-2-75, 60065, 60335, 60598, 60601, 61010

SIH10 Series Impact Hammer (0.20 to 1.00 Joule Range)

Reliable, Precision Testing for Product Durability

The SIH10 Series Impact Hammer is engineered to simulate mechanical impacts on electronic devices and electrical appliances, helping verify durability and compliance with safety standards. Each hammer is configured for one specific energy level, ranging from 0.20 Joules to 1.00 Joules, making it ideal for controlled, repeatable testing environments.

A built-in release mechanism ensures a consistent release force of 10 N, while the cone-shaped polyamide tip allows for quick and easy activation—just press it against the test subject to initiate the impact.

Standard Specifications for the SIH10 Series:

-

-

Energy Levels Available:

0.20 J, 0.35 J, 0.50 J, 0.70 J, or 1.00 J (configured per unit) -

Hammer Body:

Total mass of 1250 g

Outer diameter: 50 mm

Includes integrated release and striking mechanisms -

Striking Element:

Spherical steel hammer head with a 10 mm radius

Includes cocking knob

Mass: 250 g

Total assembled device mass: 1.57 kg -

Additional Components:

-

Release cone: 60 g

-

Helical compression spring: 9 g

-

-

Made with precision and built to last, the SIH10 Series delivers consistent, standardized impact testing in a durable and easy-to-use design. Perfect for labs, manufacturers, or anyone needing accurate energy-level verification.

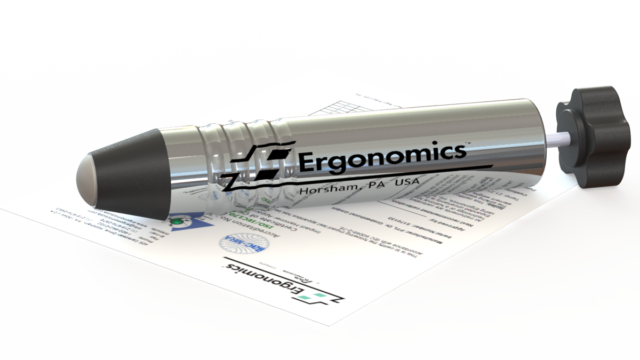

Model SIH200 Impact Hammer (2.00 Joules)

High-Energy Impact Testing for IEC Compliance

The SIH200 Impact Hammer is designed to deliver precise mechanical impacts at a fixed energy level of 2.00 Joules (Nm)—ideal for testing the durability of electronic devices and electrical appliances in accordance with IEC 60068-2-75.

Built on the same reliable platform as our SIH10 Series, the SIH200 differs in its striking element, which is specifically engineered to meet the 2.00 Joule impact requirement. The hammer features a steel tip with a 25 mm radius, weighing 500 grams, as required by the standard.

To simplify operation, the SIH200 is also available with an optional Hammer Loader Activation Device. This accessory makes loading the spring mechanism easier and more ergonomic, especially during repetitive testing cycles.

(See image below for Model SIH200 Loader.)

Key Features:

-

-

Fixed Energy Level: 2.00 Joules (per IEC 60068-2-75)

-

Striking Element:

-

Steel construction

-

25 mm radius tip

-

Weight: 500 grams

-

-

Optional Loader:

-

Reduces effort during hammer cocking

-

Ideal for high-volume or repetitive testing

-

-

Built to Last:

Constructed with precision, durability, and consistency in mind—Made in the USA.

-

Standards Compliance & Calibration Support

Both the SIH10 Series and the SIH200 Impact Hammer are designed to meet the testing requirements of leading international standards, including IEC 60068-2-75:2014, as well as IEC 60065, 60335, 60598, 60601, and 61010.

A consistent 10 N release force ensures reliable and repeatable performance across both models. Activation is simple—just press the cone-shaped polyamide tip against the test surface to trigger the impact.

Engineered with usability in mind, these hammers offer safe and efficient operation in both lab and product development settings. For customers requiring traceable calibration, we offer an optional ISO/IEC 17025-accredited calibration certificate, issued through our in-house lab—accredited by ILAC and A2LA.

Our precision-focused facility supports compliance with even the strictest international standards, giving you confidence in both the instrument and the data it delivers.